Investing in oxygen sensors for your business is a great way to maximize efficiency and gain insight into the performance of your operations. By unlocking the potential benefits of oxygen sensors, you can ensure that you are getting the most out of your investment.

From monitoring air quality to improving safety protocols, there are many ways that oxygen sensors can help improve business outcomes. In this article, we will explore how to get the most out of your investment by understanding what oxygen sensors do and how they work.

We will also provide tips on how to maintain them properly so that you can continue to reap their rewards over time.

What Are the Benefits of Oxygen Sensors?

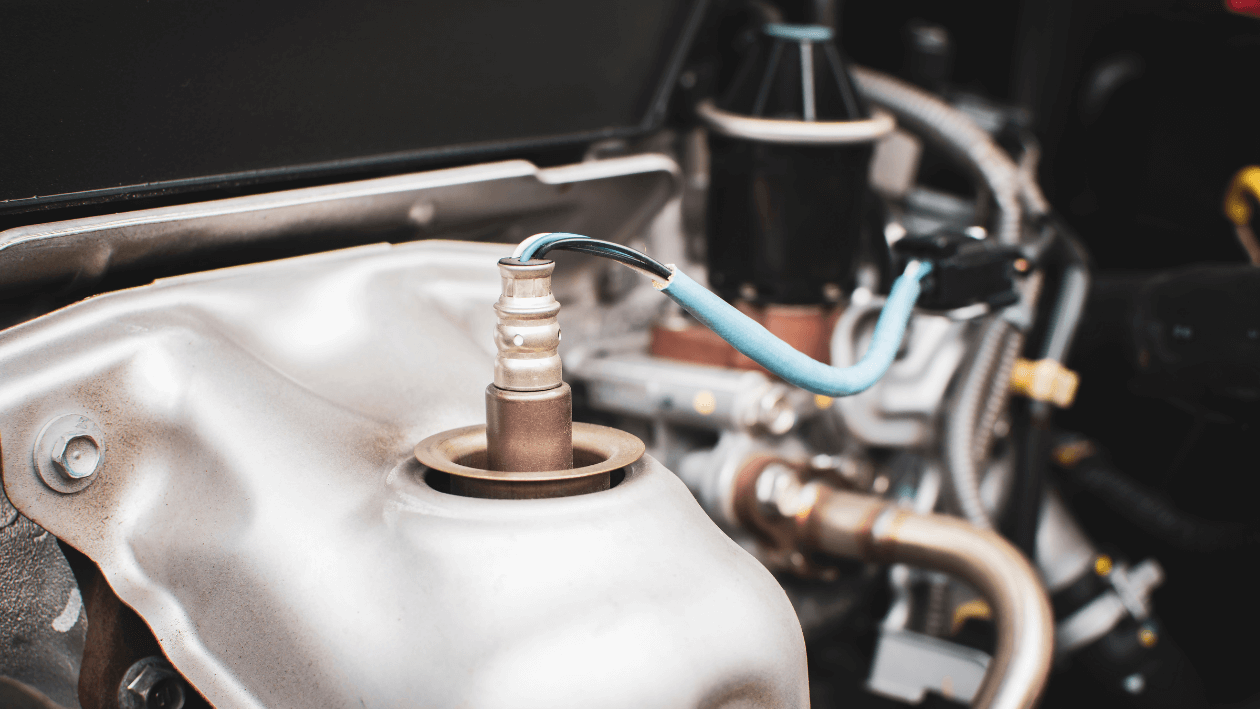

Oxygen sensors are a great investment for many reasons. They can help you monitor your engine’s performance and emissions, giving you valuable insights into how to get the most out of your car or truck. The sensors also allow for better fuel efficiency, as they work to optimize the air/fuel ratio to reduce emissions and increase power output.

Additionally, oxygen sensors offer improved safety when driving by providing information on potential problems with exhaust systems or other components before they become serious enough to damage the vehicle or its occupants.

Finally, oxygen sensors provide essential data that is used in diagnosing issues with engines so that more accurate repair estimates can be made without guesswork – saving time and money!

Understanding Installation and Maintenance Requirements

Before you can reap the benefits of oxygen sensors, it is important to understand their installation and maintenance requirements. Oxygen sensors must be installed correctly to provide accurate readings, so seeking professional assistance can help ensure successful installation.

The same goes for maintenance: If a sensor isn’t calibrated or cleaned regularly, its accuracy may become skewed over time. Regular inspections are also necessary to make sure all components remain free from debris. With proper installation and regular upkeep, your oxygen sensors will be able to function at an optimal level and keep your engine running smoothly for years to come.

Maximizing Efficiency with Quality Oxygen Sensor Solutions

When it comes to maximizing the efficiency and quality of oxygen sensor solutions, there is no one-size-fits-all solution. Different types of sensors can be used for different applications and environments, depending on the desired accuracy level, operating conditions, and cost constraints.

To get the most out of your investment you need an understanding of how these models work so that you can make informed decisions about which type would best suit your specific needs. The first step in getting the most out of an oxygen sensor is ensuring a high level of accuracy by selecting a sensor with reliable calibration capabilities and performance characteristics that are appropriate for its intended purpose.

This means paying close attention to features such as sampling rate, resolution, memory size, power consumption levels, noise rejection ratios, etc., which will determine how well it captures data accurately over time.

Additionally, environmental factors such as temperature fluctuations or excessive moisture must also be taken into consideration when choosing a model since they could affect its overall performance output.

Another important factor to consider when maximizing efficiency with quality oxygen sensor solutions is the installation technique; this involves making sure all components are correctly connected as well as having the proper setup to produce accurate readings at all times.

Finally, ongoing maintenance should not be overlooked; regular cleaning and checking for any signs of wear & tear are essential to keep your device running smoothly without interruption or failure due to malfunctioning parts or components becoming clogged up with dirt & dust particles over time.

By taking into account all these factors you’ll have peace of mind knowing that you getting maximum value from your investment while also reaping long-term benefits through improved operational efficiency across multiple sectors where precise monitoring is required including automotive engineering & medical diagnostics just to name a few!

Troubleshooting Common Issues and Potential Hazards

When it comes to using oxygen sensors, troubleshooting common issues and potential hazards is key. Although the benefits of installing an oxygen sensor are considerable, if not properly installed or maintained they can cause costly problems.

To get the most out of your investment in an oxygen sensor, it’s important to identify and address any malfunctions as soon as possible. This can include faulty wiring, a damaged exhaust system, or even clogged filters that prevent proper airflow.

Additionally, these sensors should be regularly calibrated according to manufacturer guidelines to ensure maximum performance and accuracy when reading O2 levels in the exhaust gas stream. Furthermore, environmental factors such as temperature variations must also be taken into account when calibrating the device for optimal results.

Finally, regular inspection of all components related to your oxygen sensor will help you detect any problems early on while increasing its overall lifespan and keeping maintenance costs low.

Conclusion

Oxygen sensors are a valuable tool for ensuring the safety and efficiency of many industrial processes. By investing in them, companies can unlock numerous benefits and obtain greater control over their operations.

With careful installation and regular maintenance, oxygen sensors will be able to provide long-term value, helping businesses save money while keeping employees safe. In short, an investment in oxygen sensors offers numerous tangible rewards and should not be overlooked.

Howl Movie

Howl Movie